QUESTION: What is the best way for doing a wet to dry cleaning process using a mechanical click cleaner and cleaning fluid? We purchased Stickler MicroCare from you.

ANSWER:

The best way to do a wet to dry cleaning is to use a minimal amount of the cleaning fluid. A small amount of cleaning fluid is all you need to effectively breakup and loosen any end face contamination from the ferrule end face. That same small amount of cleaning fluid is also all you need to increase the local humidity levels for totally eliminating an electrostatic charge.

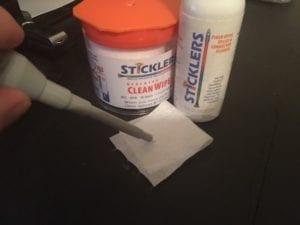

You will want to start by applying a small amount of the cleaning fluid to an optical grade clean wipe. Be careful not to over-saturate the wipe. The next step is to take the tip of the mechanical click cleaner and touch it to the wet part of the wipe. You want to apply a small amount of the cleaning fluid onto the cleaning strand. The wet the section of the cleaning strand is what will make the initial contact with the ferrule end face. The final step is to insert the cleaner into the adapter if you are cleaning an in bulkheads connector.

After you clean the in bulkhead connector, you need to inspect and clean the connector on the cable assembly to prevent cross contamination. You will want to repeat the step of touching the cleaner’s tip into the wet part of the wipe. This will reapply a small amount of cleaning fluid to next section of the cleaning strand. The final step is to attach the end cap onto the barrel of the cleaner, insert the connector into the end cap, and engage the cleaner.

ADDITIONAL CONTENT & RESOURCES:

- Category Resource: FOC Cleaning Page

- Find More Information in this Blog: The art of cleaning: Follow these specific cleaning techniques during fiber optic cable assembly manufacturing and installation

- Visit MicroCare Sticklers® Resource Page

Have a technical question for Fiber Optic Center?

Please email your question to AskFOC@focenter.com and we will respond ASAP.

In addition to replying, we will post your question and our answer here on focenter.com. Everyone remains anonymous when we post so feel comfortable asking. You can also search your question and others in our content search.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.