QUESTION: What happens if there are dust particles on one of the connector end faces during the connector mating process?

ANSWER:

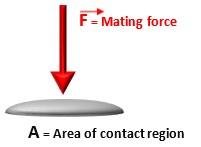

Mating connectors with dust will embed the debris into the ferrule end face causing permanent scratches and pits. The way to calculate contact pressure (P) is to divide the normal force divided by the surface area or simply P=F/A.

If we assume a connector has mating force of 3kg (6.6 lbs) and that the contact area of the two mated connectors is 200µm (0.00787 inches), the contact force between of the mated connector pair in the contact zone is 147N/m2 (21 psi). This is enough pressure between the two mated ferrules to embed the dust particles into the ferrule end faces creating scratches and pit marks in the glass of the fibre as well as on the surfaces of the zirconia ceramic of a single fiber ferrule and polymer composite materials used for MT ferrules. Scratches and pits located in the contact will have a negative impact of the signal performance and spike the inspection losses and disrupt back reflectance for angles polished connectors.

ADDITIONAL CONTENT & RESOURCES:

- Category Resource: FOC Cleaning Page

- Find More Information in this Blog: The art of cleaning: Follow these specific cleaning techniques during fiber optic cable assembly manufacturing and installation

- Visit MicroCare Sticklers Resource Page

Have a technical question for Fiber Optic Center?

Please email your question to AskFOC@focenter.com and we will respond ASAP.

In addition to replying, we will post your question and our answer here on focenter.com. Everyone remains anonymous when we post so feel comfortable asking. You can also search your question and others in our content search.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.