Where can I get a little bit of Teflon? ÅngströmLink AL-2233 is basically that.

A Teflon-like polymer dissolved in an evaporative solvent. To get a thin layer of ‘almost -Teflon’, make a thin layer of AL-2233 and let the solvent evaporate.

What will be left behind is an amorphous polymer layer that:

- Can range in thickness from <10 nm to 10u thick (anti-reflective lens coating or cladding for a waveguide)

- Has a Refractive index of 1.33 (matches water)

- Is very hydrophobic (like Teflon, can be used to mask areas from other coatings or as an optical grade mold release)

- Is optically clear (in such thin layers)

Fluorination is the thing that makes AL-2233 so much like Teflon.

Fluorine is the atom that gives the properties of low refractive index and low surface energy (the hydrophobic, non-stickiness of the surface).

There are not many things that have much affinity for fluorine, so the solvent for AL-2233 has to be fluorinated too. But the solvent is very volatile and really serves as the vehicle to deliver the fluorinated polymer to the surface being coated.

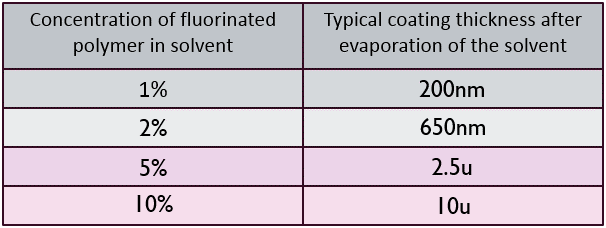

AL-2233 can be applied by spin coating, spraying, dipping, etc. When the solvent evaporates it leaves behind the fluorinated polymer layer. Final layer thicknesses are easily controlled by adjusting the concentration of the fluorinated polymer in the solvent to begin with. In a single dip process, typical layer thicknesses left after evaporation of the solvent are:

Layer thickness of less than 200nm can be obtained by simply diluting the 1% concentration with more solvent. Dilution can proceed to the point where the layer thickness left behind after evaporation is essentially one molecular layer thick – all that is needed for an effective surface treatment!

So if you ever wished you had a little bit of Teflon, in a thin layer, AL-2233 may be a solution for you.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.