Staging Multi-Component Page

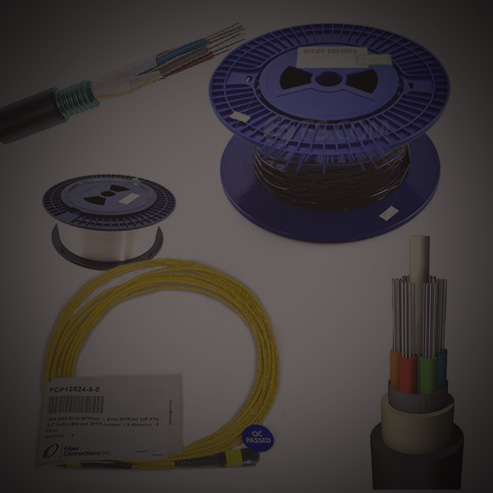

Preferred choice for many of the world’s fiber professionals

In these key technology areas, we are "at least as technical as the manufacturer" about the products we sell.

Partner Selection

Providing the fiber industry with only the highest quality components, systems and technology, our supplier selection process begins with the long-term commitment of the supplier to the product line. We have firsthand knowledge and history of quality issues related to specific parts, and close relationships with individuals at all levels within the supplier’s company.

read more

Customer Solutions

Proud to be the industry connection to the most innovative optical products, technologies and technical experts while integrating this manufacturing knowledge and vast experience into our customers’ worldwide operations. Several areas of specialization and expertise, in which we are the industry leader, make FOC the preferred choice for many of the world’s fiber professionals.

read more

Corporate Citizen

Though FOC has always supported a myriad of non-profit, they remained private prior to launching FOC Corporate Citizen. Through Corporate Citizen we intend to bring greater awareness and support to the causes we care so deeply about.

read moreAnswers to your most pressing fiber and cable questions.

Search a comprehensive database of resources, including technical papers, best practices, tips, FAQs, and more.

Fiber Optic Center

Corporate Statement

To listen to and solve our customers’ challenges, understand the entire fiber-optic cable assembly process, and provide solutions to produce the highest quality fiber-optic equipment and supplies.

We strive to build strong customer and supplier relationships, maintain inventory to meet schedules and deliver complete value-added solutions with the best technical and customer support in the industry.

We are committed to both empowering our employees to perform their daily tasks with ease in a professional, family-friendly high quality of work-life environment and become good neighbors within our community through engagement, volunteerism and respect.

Fiber Optic Center

Core Values

Core values are the foundation on which we perform work and conduct ourselves. In an ever-changing

world, core values must be constant and consistent in our work, interaction with each other, the strategies we employ to fulfill our mission.

Celerity

React with swiftness and make it happen

Hard Work

Strive to lead in effort and endurance

Helpfulness

Give help or being ready to do everything to help

Integrity

Know and do what is right

Knowledge

Be industry leader of technical information

Honesty

Earn trust, earn respect

Respect

Treat others the way you want to be treated

Responsibility

Embrace opportunities to contribute

Teamwork

Work collaboratively to be most efficient, organized and happy

Fun

Have fun. It builds trust and improves communication and creativity.

Lighting the world

The products we sell are based on fiber optics or other light-centric technologies such as lasers and optical coatings.

Fiber Optic Center (FOC) was founded in late 1991 in downtown New Bedford, MA, USA, at least in part because of the desire to provide a convenient, safe, practical and distinctive location for employees and others with whom we would be doing business: suppliers and customers from all over the world.

New Bedford was known in the 19th Century as "the city that lit the world", because as the active seaport which was home to the worldwide whaling industry, its products were used to light the lamps and later lighthouses throughout the U.S. and elsewhere. Whaleships were at sea for 3 or more years at a time in every direction, including both poles and everywhere in between. On returning to the home port, goods gathered overseas were shared with others, as were stories of people, customs and cultures. Immigrants came from far places to man the ships, and many stayed and settled when their sailing days ended.

FOC continues the new tradition of lighting the world, in that the products that FOC sells are based on fiber optics or other light-centric technologies such as lasers and optical coatings. We also see the entire planet as our market and our source of supplies, and therefore select the best and highest quality to offer to those who depend on us to get their job done.

FOC is located in a 200 year old stone and brick building in the New Bedford Whaling National Historical Park, on a cobblestone street. We look out over New Bedford harbor and the #1 fishing fleet in the U.S. (measured by the dollar value of the catch).

FOC has always supported the non-profit organizations below privately through donation and volunteerism until launching the FOC Corporate Citizen. Through Corporate Citizen we intend to bring greater awareness and support to the causes we care so deeply about.

Featured Products

Fiber Optic Center features products to highlight attributes that deliver value to end-users and differentiate a product in the market. Selection is based on but not exclusive to design, quality, functionality, and experience.

Dymax OP-81-LS Hybrid UV & Heat Cure Adhesive

This low Shrink™ OP-81-LS epoxy cures in seconds upon exposure to broad-spectrum light for fast, precise optical assembly. It has very low volumetric shrinkage during cure, low coefficient thermal

Find out more

ÅNGSTRÖMBOND® 9123

This low viscosity system produces a very high strength bond for glass, metal, ceramics and most plastics. This epoxy utilizes the most popular chemistries used for terminating connectors.

Find out more

HERNON TUFFBOND 302 GENERAL ROOM TEMP CURE EPOXY (50ML)

Hernon Tuffbond 302 is a modified epoxy adhesive that provides a very fast room temperature cure. Tuffbond 302 exhibits very good moisture chemical and heat resistance.

Find out moreResearch Epoxy, Adhesive and Fiber Coating Materials

What Epoxy, Adhesive or Fiber Coating is Best for your Termination or Application

Termination Epoxy Matrix

- Single Fiber, Single Mode And Multimode Terminations Product

- Multi-Fiber, MT And MT-RJ Terminations

- Plastic Fiber Terminations

- Field Termination, Quick Cure Product

UV Curable Optical Adhesive or Fiber Optic Coatings Matrix

| Polishing Step | Color / Material / Grit Size | Pressure1/Pad | Velocity | Time | Fluid | Usage3 | Part Number |

|---|---|---|---|---|---|---|---|

| Epoxy Removal3 | Purple-Gray / Silicon Carbide / 16um

|

0.1 lbs / 70 D | <100 rpm | 15-30 sec. | Water | 1-5 | SC16F503N100 |

| Rough Polish | Brown / Diamond / 5um | 0.35 lbs / 70 D | 120 rpm | 60 sec. | Water | 10-30 | D5BF503N1 |

| Medium Polish | Purple / Diamond / 1um | 0.35 lbs / 70 D | 120 rpm | 60 sec. | Water | 20-30 | D1KT503N1 |

| Final Polish | White / SiO2 / Sub-Micron | 0.35 lbs / 70 D | 120 rpm | 60-90 sec. | Water | 5 | ULT02605503N100 |

| Epoxy Removal3 | Yellow-Grey / Silicon Carbide / 5um | 0.1 lbs / 80 D | <100 rpm | 15-30 sec. | Water | 1-5 | SC16F503N100 |

| Medium Polish | Purple / Diamond / 1um | 0.25 lbs / 80 D | 120 rpm | 60 sec. | Water | 20-30 | D1KT503N1 |

| Final Polish | White / SiO2 / Sub-Micron | 0.25 lbs / 80 D | 120 rpm | 60-90 sec. | Water | 5 | ULT02605503N100 |

| Final Polish | White / SiO2 / Sub-Micron | 0.25 lbs / 80 D | 120 rpm | 60-90 sec. | Water | 5 | ULT02605503N100 |

| Final Polish | White / SiO2 / Sub-Micron | 0.35 lbs / 70 D | 120 rpm | 60-90 sec. | Water | 2 | FOS-22 |

| Final Polish | White / SiO2 / Sub-Micron | 0.35 lbs / 70 D | 120 rpm | 60-90 sec. | Water | 1 | FOS-01 |

| Final Polish | White / SiO2 / Sub-Micron | 0.35 lbs / 70 D | 120 rpm | 60-90 sec. | Water | 5 | XF5D |

Fiber Optic Center Technical Paper:

Specialty and Polarization-Maintaining Fibers Explained

- Specialty Fiber Explained - “Discusses the wide range of specialty fibers, and special issues encountered in the preform and draw process.”

- Optical Fiber Draw Towers: Procedures For Drawing Specialty Fibers - “Focuses on the second part of the optical fiber manufacturing process.”

- Polarization-Maintaining Fibers Explained - “Discusses polarization-maintaining (PM) fibers and the various approaches used to make them.”

Fiber Optic Center

Home to world-class talent in the global advancement of fiber optics

Why Work at Fiber Optic Center?

Fiber Optic Center, Inc., (FOC) is an international stocking distributor helping our customers make the best cable assemblies in the world. These cables go into global systems supporting current telecommunications and will enable IOT for the future. Based on years of global experience and on our teammates’ vast manufacturing knowledge, we have become a highly specialized technical expert, an industry leader, and preferred choice for most of the world’s top fiber professionals. We have developed industry connections to the most innovative optical products and technologies. This coupled with a deep understanding of the products we sell and processes we support allows us to add significant value to our customers’ operations. Headquartered out of Southeastern Massachusetts, conveniently linked to both Providence, RI and Boston, MA, we are the trusted resource globally for fiber optic components, equipment, supplies, latest technologies, innovative automations, and industry talent.

Build that future with Fiber Optic Center, Inc.

For more information contact: careers@focenter.com with your résumé or questions.

Fill out our online application here.

Your Technical Resource for Epoxy

- KELLY BARKER

- 508-717-8426

- KBARKER@FOCENTER.COM

Click here to request an appointment with Kelly Barker

Browse our complete product line for cable assembly production, services, additional fiber applications and specialty applications, by clicking links below.

Cable Assembly Production

Shop allAdditional Fiber Applications & Specialty Applications

Troubleshooting Expertise to Overcome the Many Preform Fabrication and Fiber Draw Issues Manufacturers Face When Producing Specialty Optical Fibers

Fiber Optic Center offers Fiber Process Development and Manufacturing consulting services to manufacturers of specialty optical preforms and fibers

SERVICES INCLUDE, BUT NOT LIMITED TO:

- Fiber Process Development Assistance

- MCVD System Selection for Preform Production

- Preform Fabrication by MCVD Consultation

- Fiber Optic and Polymer Fiber Draw Towers R&D

- Soft Glass Fiber Draw Towers Consultation

- Proof Test Equipment and Rewind System Consultation

- Specialized gas handling systems

- Fiber Measurement Consultation

- Rare earth doped fibers process development

- Optical Fiber Preform

- Post-Installation for Exacting Product Specs

- Personnel Training

- Standard Operating Procedure (SOP) Writing

Answers to Fiber Process Manufacturing Questions

Search a comprehensive database of resources on Rare Earth Doped Optical Fiber Recipes, Fiber Draw, MCVD and Fiber Caotings

- Lorem, ipsum

- Pellentesque

- Fusce quis

- Lorem, ipsum

- Pellentesque

- Fusce quis

- Lorem, ipsum

- Pellentesque

- Fusce quis

- Lorem, ipsum

- Pellentesque

- Fusce quis

- Lorem, ipsum

- Pellentesque

- Fusce quis

- Lorem, ipsum

- Pellentesque

- Fusce quis

- Lorem, ipsum

- Pellentesque

- Fusce quis